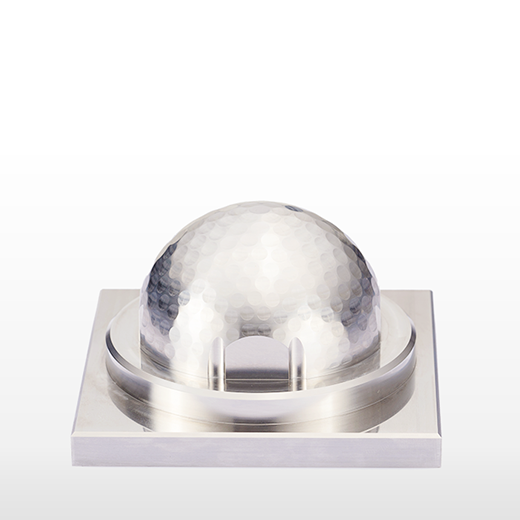

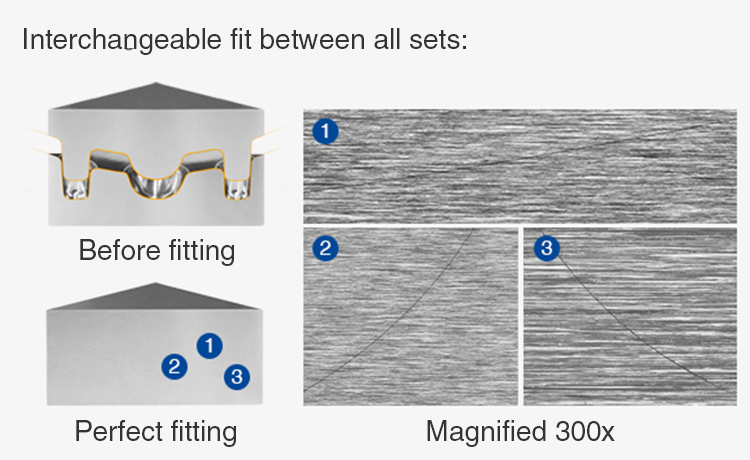

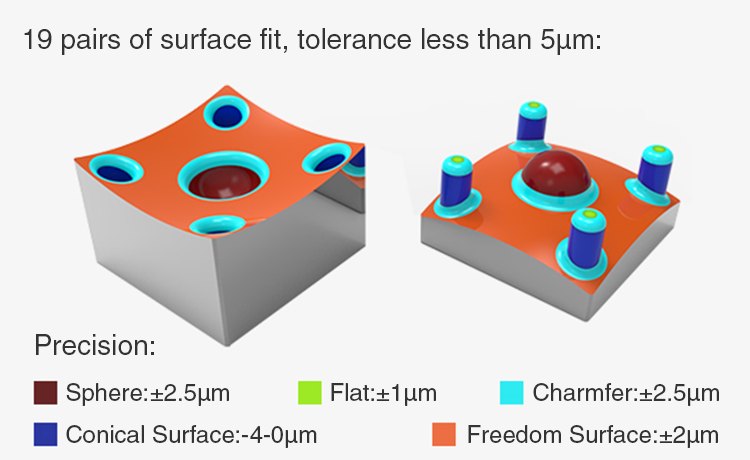

The quality of die molds influences the product’s quality directly. As the demands for better product quality continues to increase, resulting in higher requirements on the surface effect and precision of mold. On one hand, good surface quality makes it easy to demold, improves product quality and extend service life. On the other hand, high precision and interchangeability can reduce manual participant in molding process, improve efficiency so that you can respond to your customers faster. These make it really necessary for you to transplant Jingdiao die mold solution to your sites. Not because we can help you to machine one pair of precision die mold, but because it’s possible to realize standardized mold making without secondary operation by using our solution. As we can accurately control the fitting tolerance within 5μm and stably machine optical mold with 10nm surface roughness.

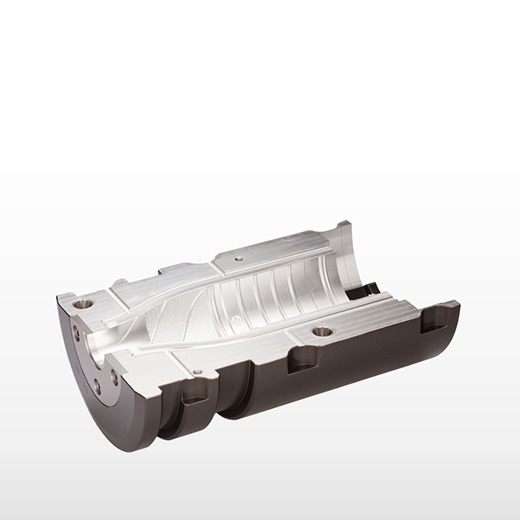

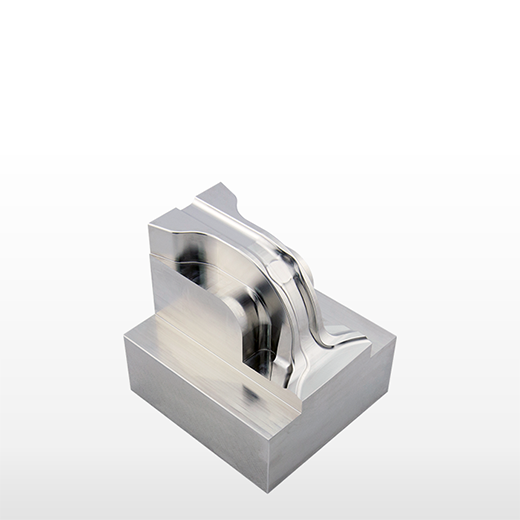

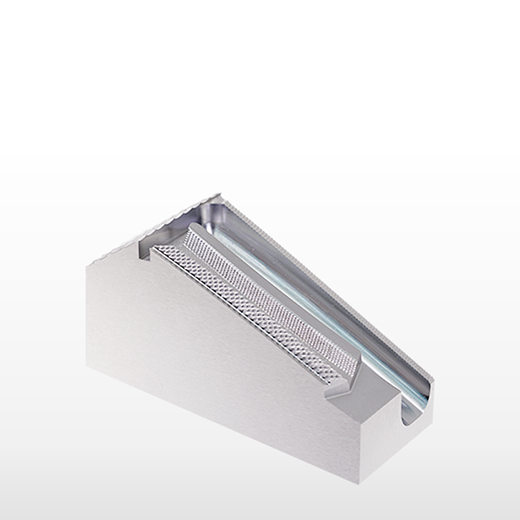

Example Workpiece

Machining Center

Inverted L braced structure used on X-axis improves structure rigidity and vibration resistance;

Damping material filled in main structural parts improves vibration resistance;

Heat insulation applied to main structural parts reduces effect of temperature;

Compensation technology of control system improves machining accuracy and precision;

Automatic door optional on the right side of machine to realize large-scale die mold processing.

Application of full-closed control system can realize "0.1μ feeding, 1μ cutting";

Reasonable assignment of quality on each axis and better dynamic performance due to portal design;

Strong vibration resistance capability gets small tool wear;

Closed-loop control effectively compensates driving error and screw extension caused by heat;

Cooling on bearing housing, guide screw, motor of rotary table to improve temperature stability.

Technology

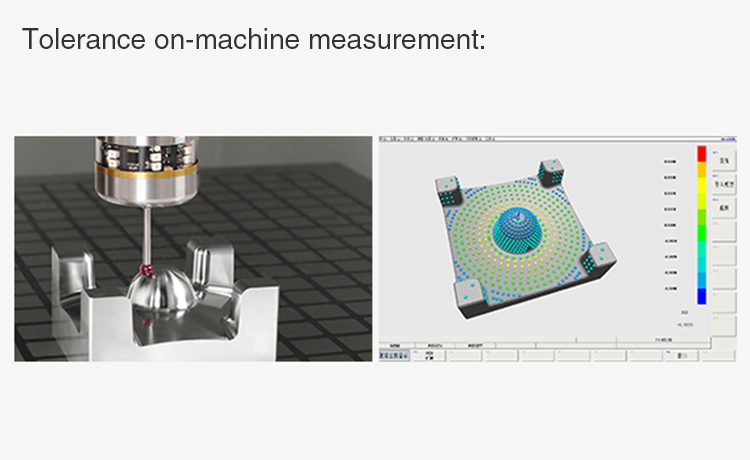

The idea of our solution is controlling the tolerance of each process within 5μm, cause if each process is controlled precisely the mold will fit perfectly. By using Jingdiao’s precision control technology, it won‘t be a difficult task due to the temperature fluctuation inside machine can be controlled less than 2℃, tool wear is smaller than 2μm and machining at the speed with lowest vibration. Moreover, Jingdiao OMIM technology can inspect machining tolerance of each process, based on the data shown on control system, operator can decide whether to carry out the next process or not, so that every decision is well-founded.

+ READ MORE

Service

Machine selection service, customization and upgrade, engineering service and technical training are available for you. Do not hesitate to contact us.

Know more, rest assured more.