Complex structure, high material removal rate, extremely high requirement for effects of detail are the main features of medical parts machining.The application of hard-to-cut materials, such as titanium alloy, makes it even more difficult to realize precision machining medical parts.To meet the needs of hard-to-cut material in machining performance, efficiency and accuracy,we‘ve been focused on the research of machining technology of hard-to-cut material,and make a lot of tests and have gradually formed a set of mature and reliable technical solutions.

Example Workpiece

Machining Center

Application of full-closed control system can realize "0.1μ feeding, 1μ cutting";

Closed-loop control effectively compensates driving error and screw extension caused by heat;

In line with center of gravity driven and has higher dynamic response;

Strong anti-vibration capability gets small tool wear and good surface roughness;

Intelligent 5-axis workpiece alignment is achievable due to the application of OMIM technology;

High-efficient 5-axis simultaneous machining thanks to RTCP function in control system.

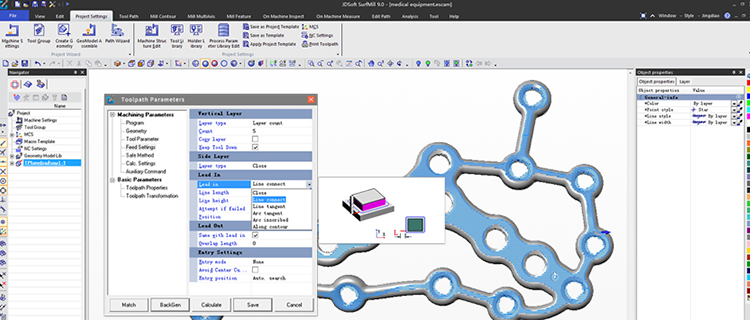

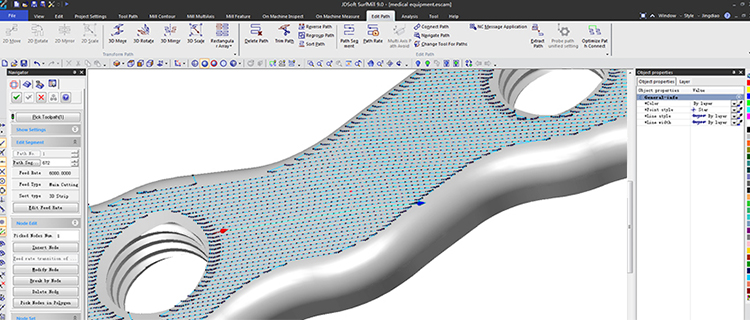

Software

Various processing strategies and path optimization methods in Jingdiao CAD/CAM software:

The path editing module offers a variety of tool feed modes, such as connection of straight line, internally tangent of arc and tangency of arcs, to ensure the fluency of processing and reduce the traces of tool feeding.

Through reducing the depth of cut on profile sharp corner in roughing, and machine vibration in high-speed finishing, to extend life of cutting tools and improve the surface quality of workpiece.

Various wave types can be created, such as triangle wave, sine wave, trapezoidal wave, to ensure the cutting edge of grinding head is fully utilized. The intelligent cone wave function automatically generates a suitable path according to the angle of the grinding head, reducing the difficulty of operation.

It supports path node editing, sorting, interrupting and some other related functions, and can rotate, translate, and array the path to achieve free and fast adjustment of processing order.

Service

Machine selection service, customization and upgrade, engineering service and technical training are available for you. Do not hesitate to contact us.

Know more, rest assured more.