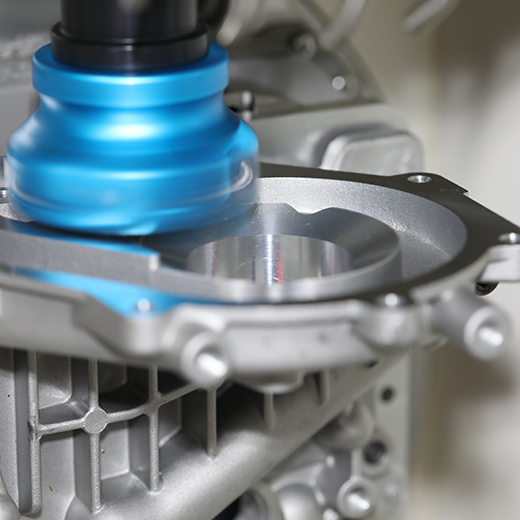

In real production, there are lots of factors impact on machining efficiency and machining results. Jingdiao accessories can help reduce the negative impact and improve accuracy and efficiency.

CONTACT USRealizing Fast, Accurate and Efficient Clamping

Equipped with standardized interface, Jingdiao quick-change clamping system can be connected with vise, permanent magnetic chuck, customized fixture and so on. You can use them in any combination to fulfill variety of machining needs including multi-axis machining, multi-process machining, automation and measurement.

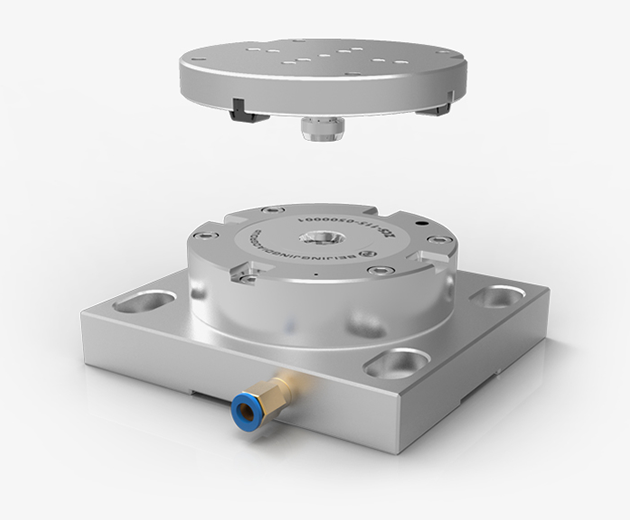

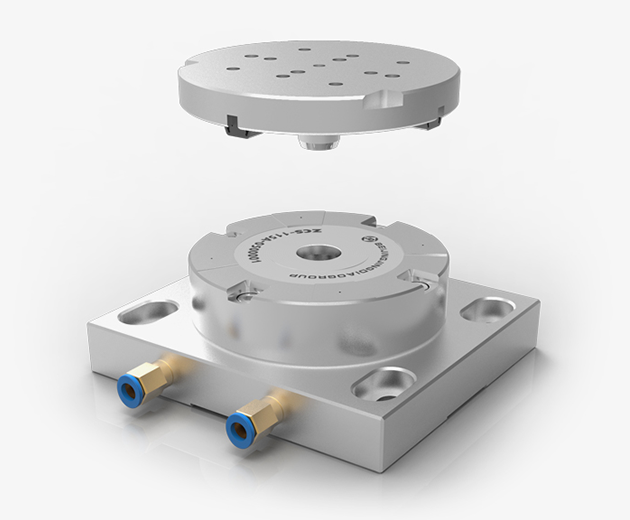

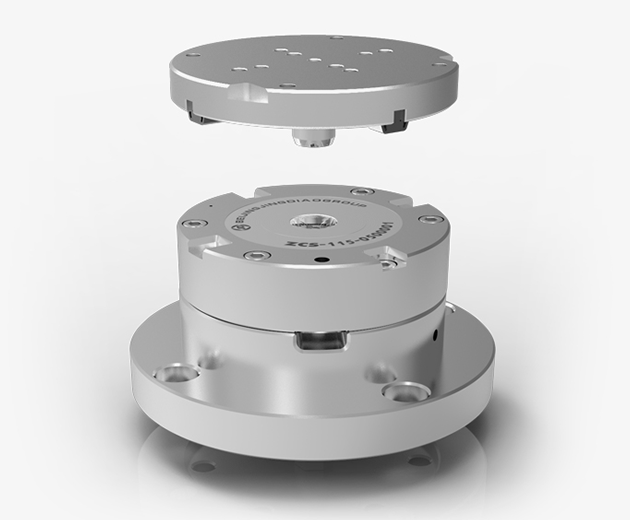

←Quick-change Clamping System

Regular quick-change clamping

Basic Specification

| Repetitive Position Accuracy: 3μ |

| Workpiece Size: 150*150mm |

| Workload: 12kN |

| Unlocking Pressure: 0.5MPa |

| Weight: 1.85kg |

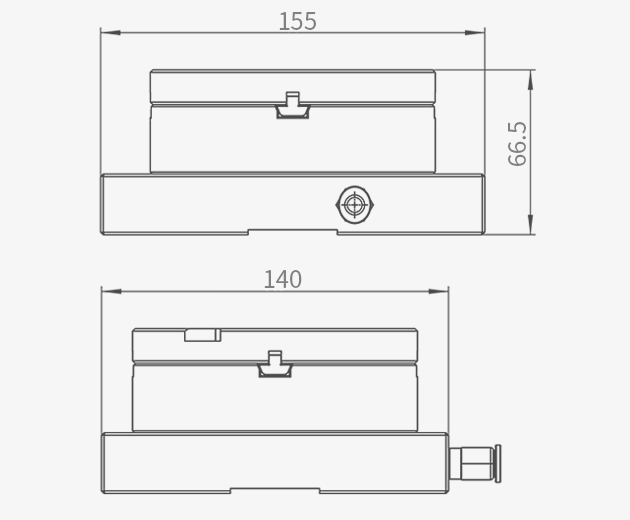

Dimension

Product Instruction

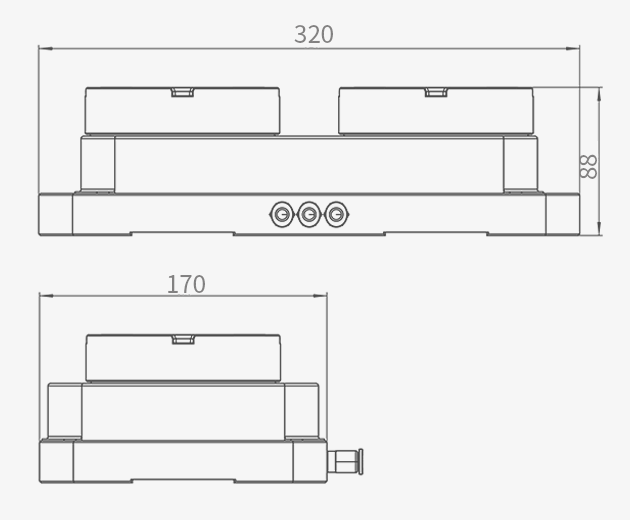

Two point quick-change clamping system

Basic Specification

| Repetitive Position Accuracy: 3μ |

| Workpiece Size: 150*350mm |

| Workload: 12kN |

| Unlocking Pressure: 0.5MPa |

| Weight: 1.85kg |

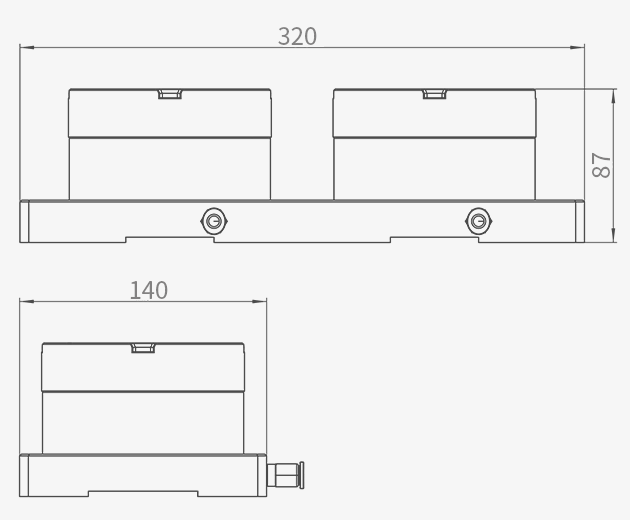

Dimension

Product Instruction

Self-cleaning function, more suitable for automation

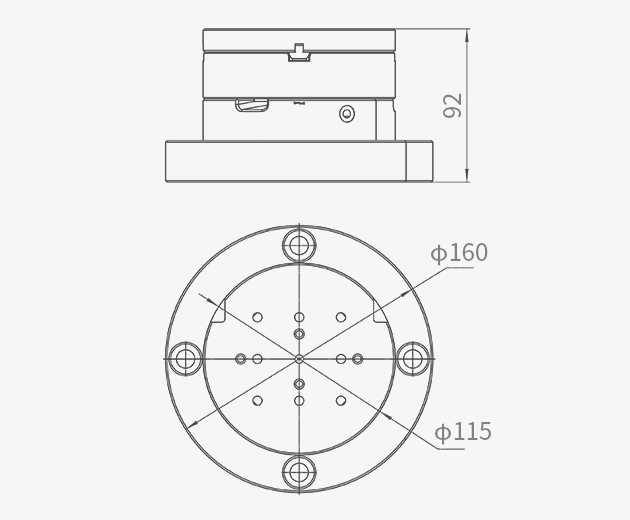

Basic Specification

| Repetitive Position Accuracy: 3μ |

| Workpiece Size: 150*150mm |

| Workload: 12kN |

| Unlocking Pressure: 0.5MPa |

| Weight: 1.85kg |

Dimension

Product Instruction

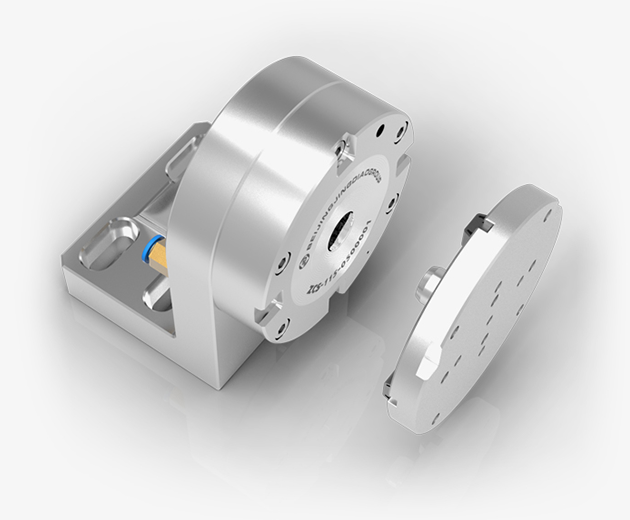

Horizontal quick-change clamping

Basic Specification

| Repetitive Position Accuracy: 3μ |

| Workpiece Size: 150*150mm |

| Workload: 12kN |

| Unlocking Pressure: 0.5MPa |

| Weight: 1.85kg |

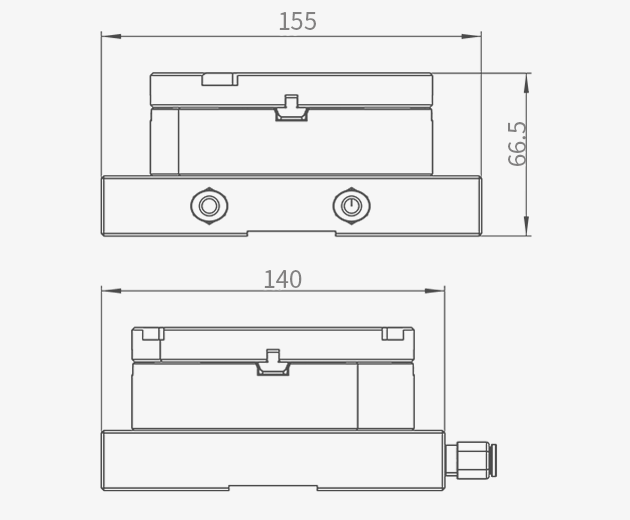

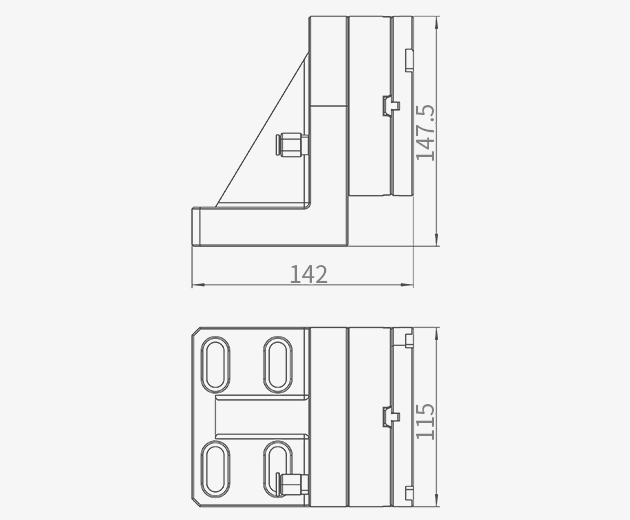

Dimension

Product Instruction

More suitable for multi-axis machine tools

Basic Specification

| Repetitive Position Accuracy: 3μ |

| Workpiece Size: 150*150mm |

| Workload: 12kN |

| Unlocking Pressure: 0.5MPa |

| Weight: 1.85kg |

Dimension

Product Instruction

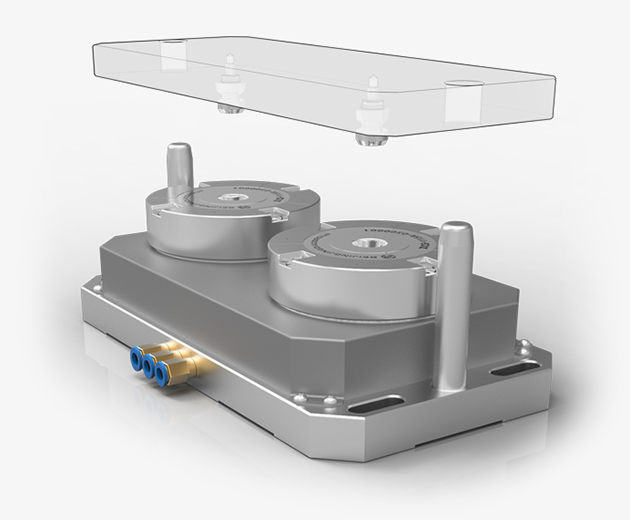

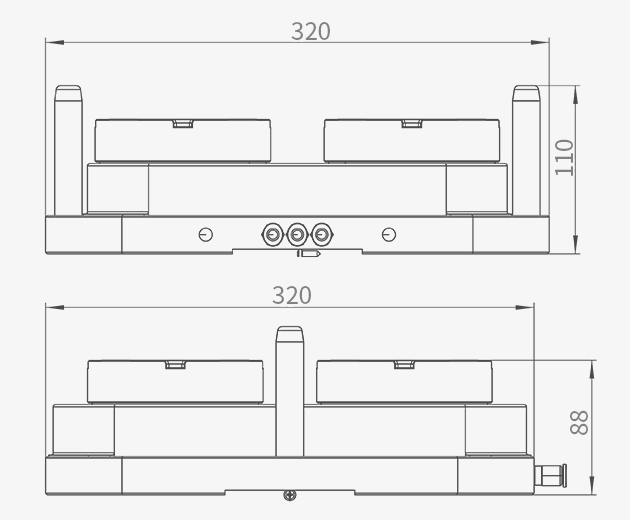

Self-cleaning function and state detection function, more suitable for automation

Basic Specification

| Repetitive Position Accuracy: 3μ |

| Workpiece Size: 350*350mm |

| Workload: 12kN |

| Unlocking Pressure: 0.5MPa |

| Weight: 1.85kg |

Dimension

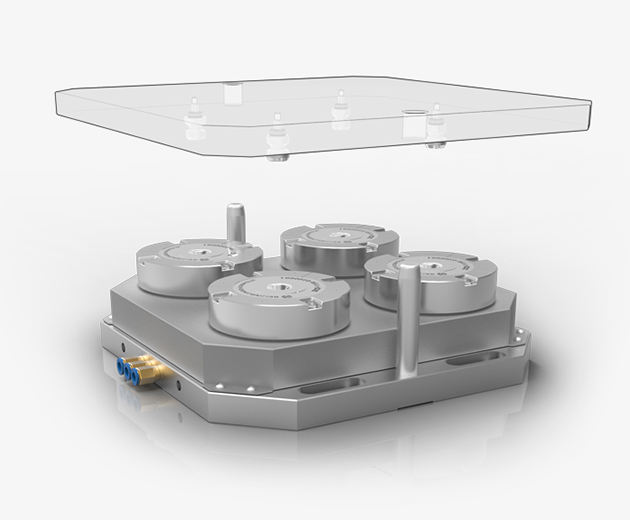

Four point quick-change clamping system with self-cleaning and state detection function

Basic Specification

| Repetitive Position Accuracy: 3μ |

| Workpiece Size: 150*150mm |

| Workload: 12kN |

| Unlocking Pressure: 0.5MPa |

| Weight: 1.85kg |

Dimension

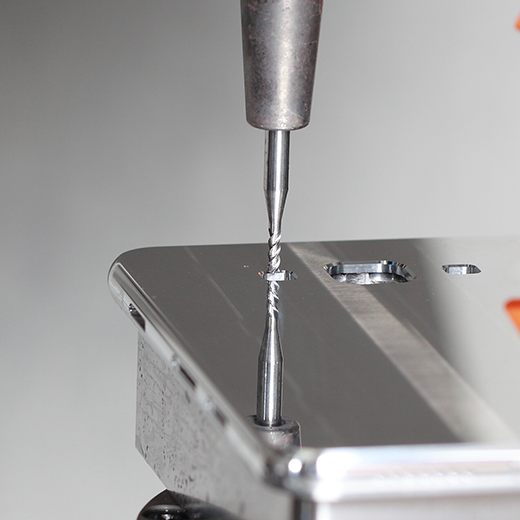

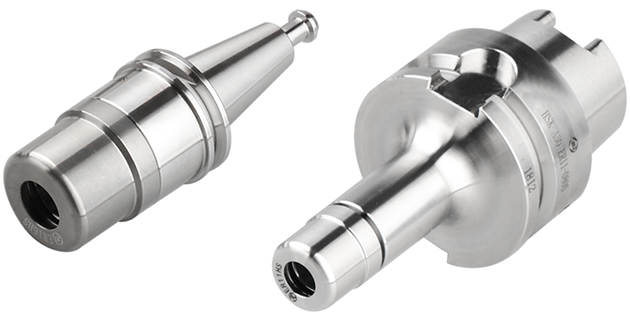

Fully Release the Performance of Cutting Tool

Anticorrosive, no wind resistance design, good dynamic balance are the key features of Jingdiao tool holders. These make Jingdiao tool holders have good clamping performance including high clamping accuracy, less generation of oil mist and low vibration in high-speed machining.

←Tool Holder

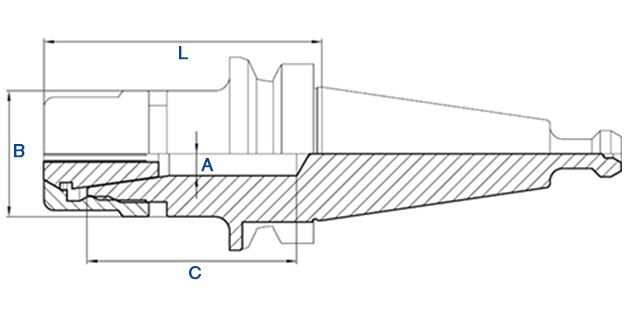

Specification

| Name | Size(mm) | |

| A/B/C/L | Thread | |

| BT30-ER11-85S | 7.5/19/35/82 | M14X0.75 |

| BT30-ER16-60S | 10.5/30/50/67 | M22X1.5 |

| BT30-ER16-100S | 10.5/30/50/107 | M22X1.5 |

| HSK-A40-ER16-060HS | 10.5/30/28.5/65 | M22X1.5 |

| HSK-A50-ER11-080S | 7/19/30/80 | M14X0.75 |

| HSK-A50-ER16-070S | 10.5/30/40/71 | M22X1.5 |

| HSK-A50-ER16-110S | 10.5/30/40/111 | M22X1.5 |

| HSK-E32-ER16-060HS | 10.5/30/27.5/65 | M22X1.5 |

| HSK-E40-ER16-060HS | 10.5/30/28.5/65 | M22X1.5 |

| ISO20-ER16-050HS | 10.5/30/28.5/54 | M22X1.5 |

Dimension

Low Cost of Coolant and Long Life Cycle for Cutting Tool

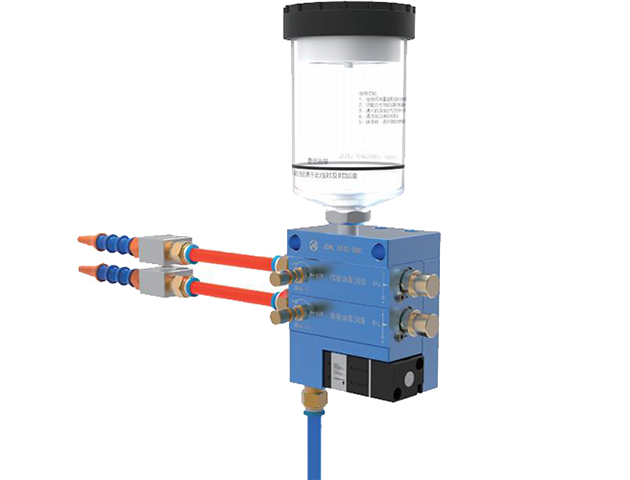

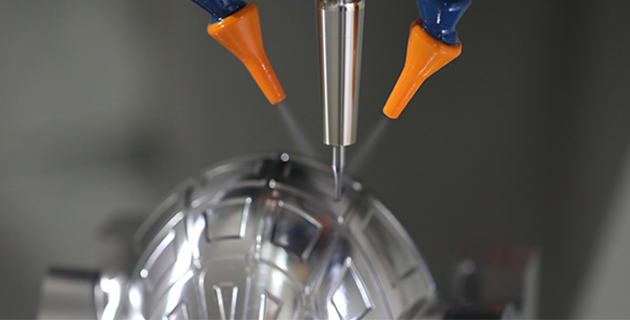

Jingdiao MQL is widely used in metal cutting area, especially in hard material processing and die mold processing. Up to 85% coolant can be saved with Jingdiao MQL, life cycle of cutting tool and surface effect of workpiece can be improved dramatically as well. By using environmental friendly coolant, there’ll be no harm to both human body and environment.

←MQL

Specification

| Item | Spec |

| Pressure | 0.5~0.8MPa |

| Working Pressure | 0.55MPa |

| Air Volume | 0~220L/min |

| Air Consumption per Nozzle | 100L/min |

| Oil Consumption per Nozzle | 0~30mL/h |

| Nozzle Number | 2 |

| Weight | 1.5kg |

| Mounting Pitch | 70mm |

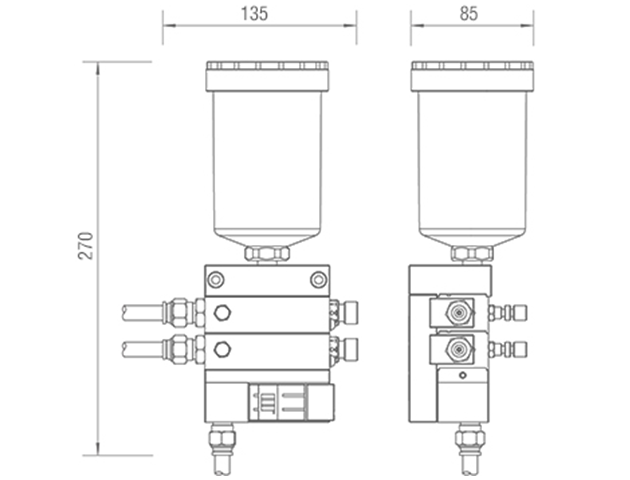

Dimension

Application

Reduce Maintenance Cost of Machine Tools

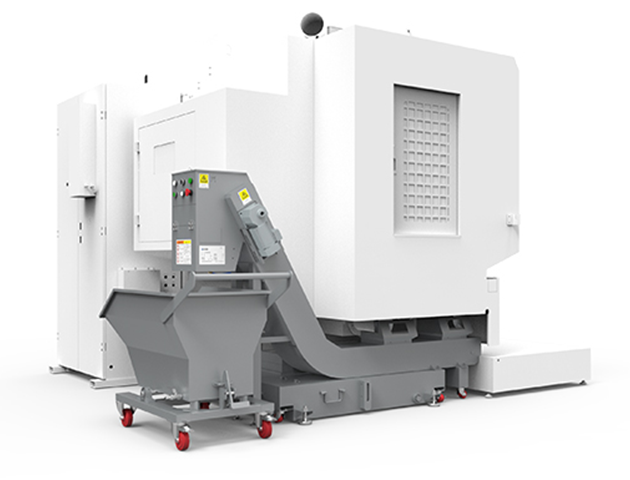

Jingdiao chip disposal system is consisted of scraper type chip conveyor, filter tank and chip bucket. It can be used for chip discharge and collection, coolant cooling and filtering. With its multi-stage filtering design and closed structure, service life of coolant can be extended effectively to provide a better protection for machining quality of high-speed machining centers.

←Chip Disposal

Specification

| Series | JDAGB240 | JDAGB280 | JDAGB320 |

| Motor Power(W) | 150~200 | ||

| Transfer Speed(m/min) | 1.7±0.5 | ||

| Chip Type | Broken Chip/Debris Chip/Powder Chip | ||

| Chip Length(mm) | ≤50 | ||

| Discharge Volume(kg/min) | ≤3.0 | ≤3.5 | ≤4.0 |

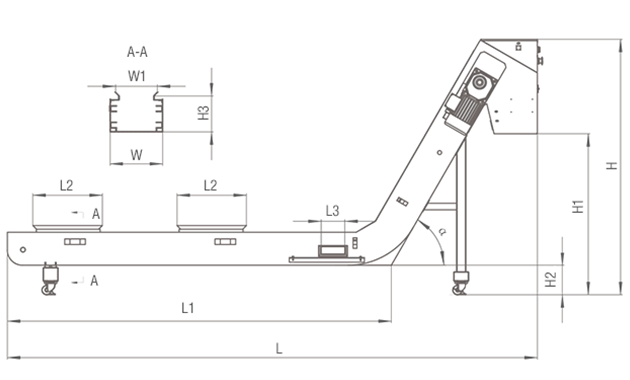

Dimension

Unit:mm

| Series | JDAGB240 | JDAGB280 | JDAGB320 |

| Total Length-L | ≤1000 | ||

| Total Width-W | 240 | 280 | 320 |

| Lift Angle-α | 30° | 45° | 60° |

|

Horizontal Length-L1 |

Customized | ||

| Import Length-L2 | |||

|

Filter Port Length-L3 |

|||

| Import Width-W1 | |||

| Total Height-H | |||

| Lift Height-H1 | |||

|

Support Height-H2 |

|||

| Import Height-H3 | |||