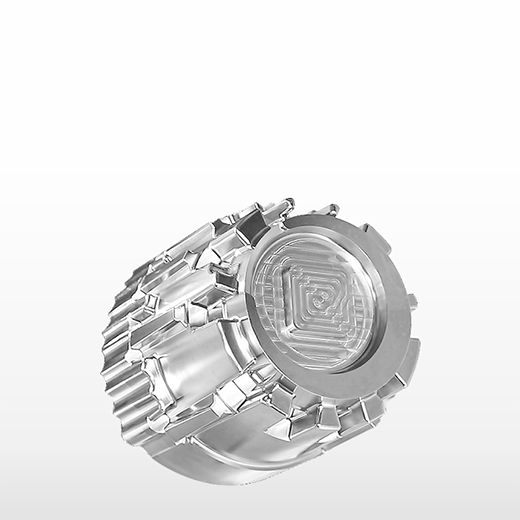

MRA600

5-axis Machining for Large Precision Parts

X/Y/Z Travel:25.6/ 23.6/ 19.7 in.

A/C Travel:-120°~90°/ 360°

Spindle Speed:20000 rpm

Table Size:Φ24.8 in.

Workload:771.8 lbs.

Highlights

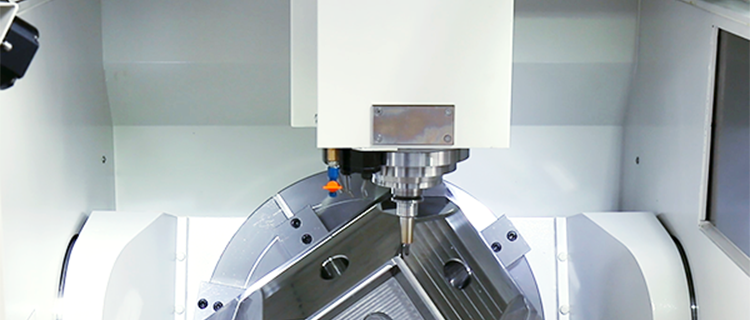

Use-friendly Structure Design

Compact design reduces floor area

23° gradient machine bed is convenient for chip disposal

Open-structure front door and top automatic door are easy for large workpiece hoisting

Perfect Choice for High-Precision Multi-Axis Machining

Maximum workload is 350kg due to application of two motors on A-axis

Reliable position machining thanks to brake mechanism on both rotary axes

Capable of using large tools and boring with JD150 spindle

Suitable for root and angle cleaning of large molds to reduce the use of EDM

Outstanding Machining Performance

Little thermal effect on machining accuracy due to dynamic portal design

Internal cooling system on both axes of rotary table

Lead screw cooling technology is used to effectively control thermal extension

Suitable for root and angle cleaning of large molds to reduce the use of EDM

Example Workpiece

Related Links