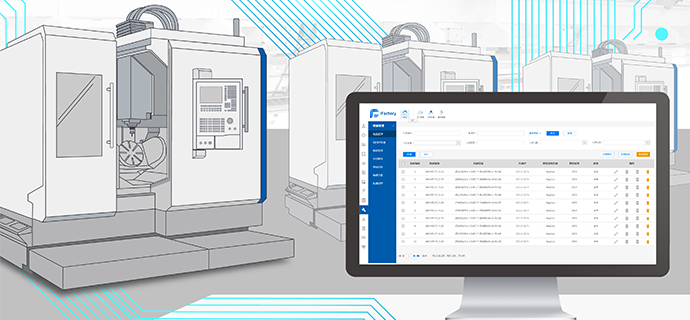

GRA100

5-axis Machining for Accessories , Optical Mirror Mold and Medical Devices

X/Y/Z Travel:15.7/7.9/7.9 in.

B/C Travel:±120°/ 360°

Spindle Speed:28000 rpm

Table Size:Φ6.3 in.

Workload:33.1 lbs.

Highlights

Stable and Reliable Structure

Guideway of beam adopts inverted "L" type support structure and height reduction to improve machine tool stability

Sinking style of positive chisel head reduces impact of slider movement on guideway straightness

Inclined design and drawer type collection box are adopted inside the machine, which is convenient for precious metal recovery

Backward equipment electrical cabinet and built-in water tank make the machine tool cover only 5.8㎡

The main machine weighs only 2.5t , which can be used upstairs

Comprehensive Guarantee for Precision

Sheet metal cover added at the top is conductive to balance the internal temperature of the machine tool

Heat preservation measures for key structural components reduces the impact of external environment

Cooling on guide screw and rotary table to improve temperature stability

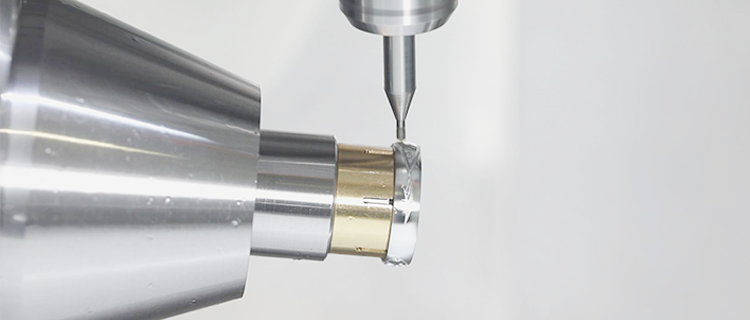

Jingdiao on-machine measurement system realizes condition monitoring of tool, fixture and workpiece to ensure machining accuracy

Outstanding Human-Machine Interaction

The height of the center of the console screen from the ground is moderate, suitable for the height of the public

The distance between work table to the ground makes internal clamping operation more comfortable

Suitable distance between front door and center of rotary table makes internal clamping operation convenient

Example Workpiece

Related Links