GRA200

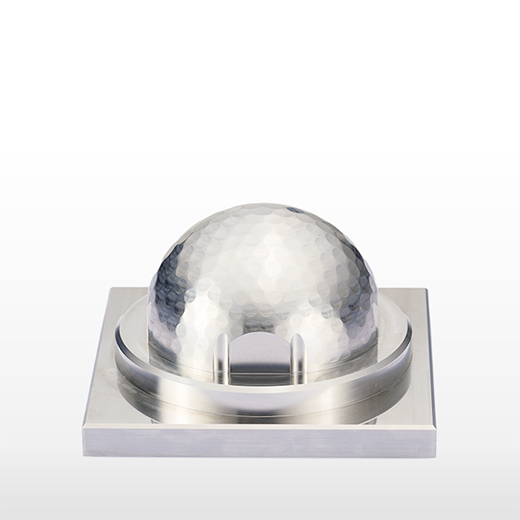

5-axis Machining for Precision Die Mold and Complex Hardware

X/Y/Z Travel:19.7/ 11.0/ 11.8 in.

B/C Travel:-120°~90°/ 360°

Spindle Speed:28000 rpm

Table Size:Φ10.2 in.

Workload:66.2 lbs.

Highlights

Optimal Structure Design

Portal design, good anti-vibration and thermal symmetry design of main body

Processing zone and non-processing zone are totally isolated to avoid damage on movement components from chip and coolant

Tool setting gauge is hidden when not used to effectively avoid collision

In line with center of gravity driven and has higher dynamic response

Outstanding Machining Performance

Application of full-closed control system can realize "0.1μ feeding, 1μ cutting"

Strong anti-vibration capability gets small tool wear

Cooling technology applied on lead screw and rotary table can effectively reduce thermal influence on machine accuracy

Brake mechanism equipped on both axes ensures high rigidity when positioning

Standard capacity of tool magazine is 36 sets, tool changing time is shorter than 1.2 sec

Excellent Human-Machine Interaction

Large window is installed on front door to observe processing

Slope structure of machine bed makes it easy for chip disposal

Distance between spindle and machine door is 459mm and is easy for changing tool manually

Distance between the center of rotary table and machine door is 329-609mm and is easy for loading, unloading workpiece

Pneumatic and lubrication components installed on the left side of machine makes it convenient to check and maintain

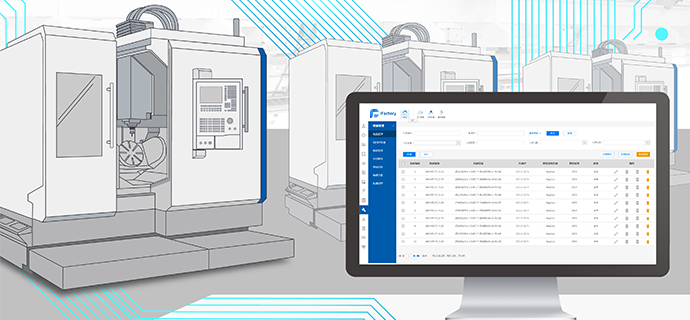

Intelligent 5-axis workpiece alignment is achievable due to the application of OMIM technology

Example Workpiece

Related Links