GRA400

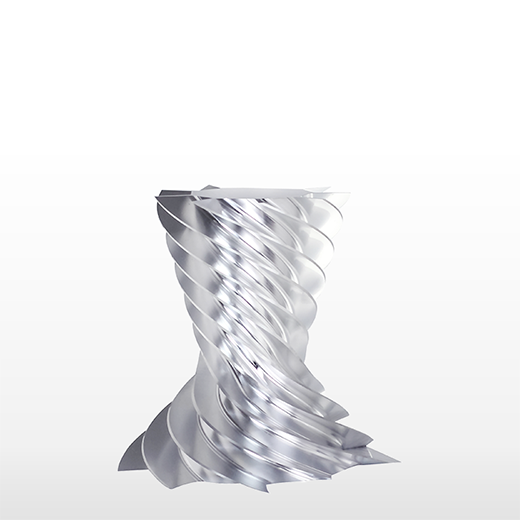

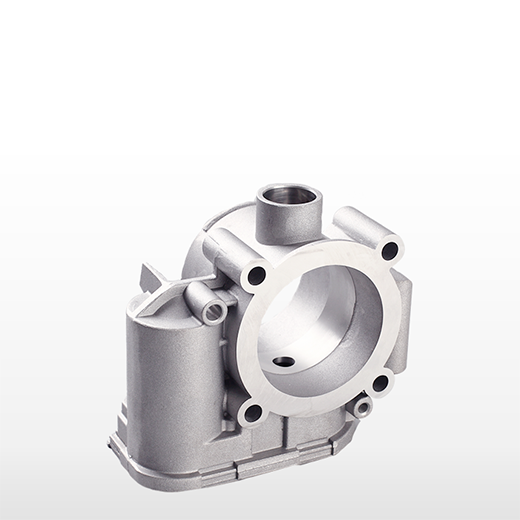

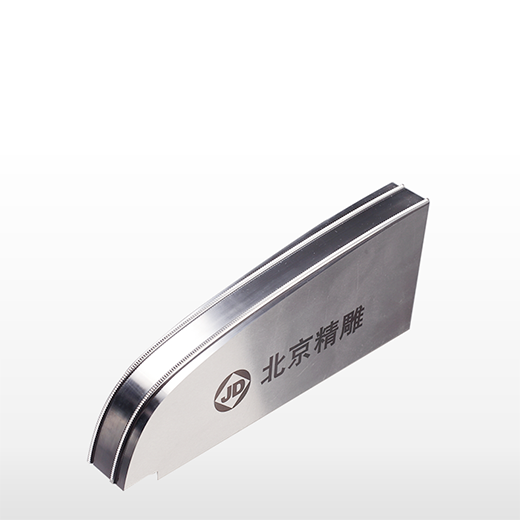

5-axis Machining for Precision Die Mold and Complex Hardware

X/Y/Z Travel:17.7/ 26.8/ 15.7 in.

A/C Travel:-120°~90°/ 360°

Spindle Speed:24000 rpm

Table Size:Φ15.7 in.

Workload:330.8 lbs.

Highlights

Reasonable Machine Structure

Reasonable assignment of quality on each axis and better dynamic performance due to portal design

Stable geometric accuracy thanks to wide section of column, three guideway of beam, short-overhang machine head ensure stable geometric accuracy

A-axis arranged along machine bed reduces impact of X-axis movement on A-axis

Outstanding Machining Performance

Closed-loop control effectively compensates driving error and screw extension caused by heat

Cooling on bearing housing, guide screw, motor of rotary table to improve temperature stability

Insulation measures are applied on key die casting components to reduce temperature effect

Fully enclosed shield outside machine reduces environment impact on external environment

Use-friendly Operation Design

Open-structure front door is easy for large workpiece hoisting

Short distance between front door and center of rotary table makes operation convenient

Pneumatic and lubrication components installed on the left side of machine makes it convenient to check and maintain

Example Workpiece

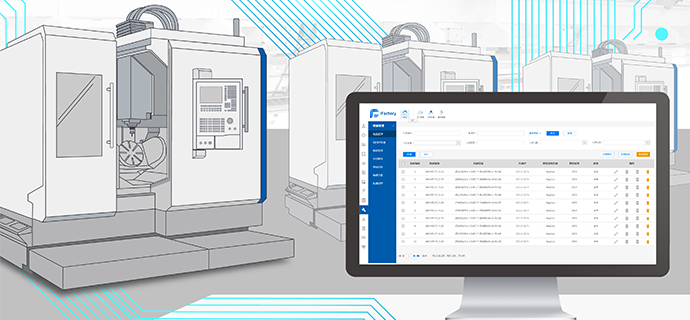

Related Links