HGA1600

Vertical Machining for Large Precision Hardware and Die Molds

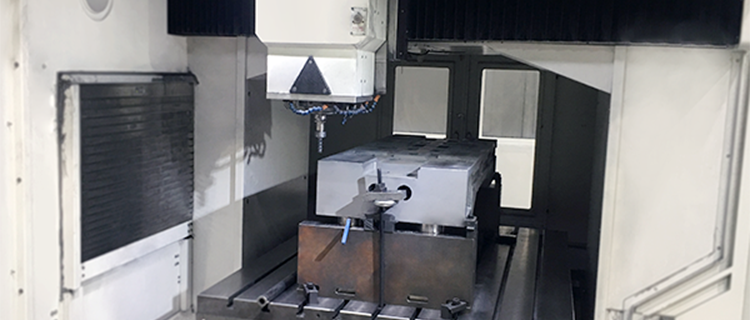

X/Y/Z Travel:63.0/ 47.2/ 23.6 in.

Spindle Speed:20000 rpm

Table Size:65.0 × 49.2 in.

Workload:6615 lbs.

Highlights

Stable and Reliable Structure

Portal symmetrical design leads to good thermal symmetry

Inverted L braced structure improves rigidity and stability of machine head

Using FEM to optimize structure and manufacture

Built-in chip disposal for chip clean up timely

Scraper type chip disposal is equipped fits a variety types of chips

Comprehensive Guarantee for Precision

Damping material filled in main structural parts improves vibration resistance

Heat insulation applied to main structural parts reduces effect of temperature

Jingdiao inverter refrigerator is used for cooling spindle and screw

Active vibration technology is used on 3-axis drive

Application of OMIM technology ensures evaluation and intelligent modification of processing result on machine

Compensation technology of control system improves machining accuracy and precision

Outstanding Machining Performance

"0.1μ feeding and 1μ cutting" capability

High-speed rigid tapping due to the application of Jingdiao high-speed synchronous spindle

Jingdiao 4-axis and 5-axis rotary tables are optional and make it possible to realize multi-axis machining

Full Consideration of Ergonomics

Lateral operation mode, hoisting space on front door, automatic door on top for loading and unloading of large workpiece and fixture

Walk-in tool magazine maintenance area makes maintaining convenient

Related Links