HGA600

Vertical Machining for Precision Hardware Parts and High-precision Die Mold

X/Y/Z Travel:23.6/ 19.7/ 10.2 in.

Spindle Speed:24000 rpm

Table Size:25.6 × 25.6 in.

Workload:661.5 lbs.

Highlights

Stable and Reliable Structure

Portal symmetrical design leads to good thermal symmetry

Inverted L braced structure used on X-axis improves structure rigidity and vibration resistance

Disc tool magazine is easy to maintain

Using FEM to optimize structure and manufacture

Small footprint due to compact internal space design

Comprehensive Guarantee for Precision

Closed-loop control system

Damping material filled in main structural parts improves vibration resistance

Heat insulation applied to main structural parts reduces effect of temperature

Jingdiao inverter refrigerator is used for cooling spindle and screw

Compensation technology of control system improves machining accuracy and precision

In Line with Ergonomics

Front door structure, operation table and worktable accord with principles of ergonomics

Overall Layout of machine makes it easy to maintain every component

Maneuver box added to tool magazine makes it easy to change tools

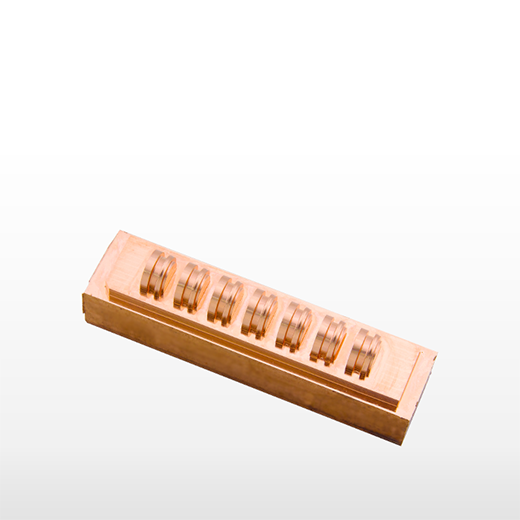

Example Workpiece

Related Links