CTA600

3-axis Machining for Precision Mold

X/Y/Z Travel:23.6/ 19.7/ 11.8 in.

Spindle Speed:20000 rpm

Table Size:25.6 × 25.6 in.

Workload:661.5 lbs.

Highlights

Optimal Structure Design

Portal symmetrical structure and good thermal symmetry

Three rails heightened structure, strong structural rigidity

Integrated chip conveyor with excellent chip evacuation capability

Outstanding Machining Performance

With spindle cooling technology

Good anti-vibration capacity

Using 150S synchronous spindle, which can realize various precision machining such as drilling, boring, tapping, milling and grinding

Machining accuracy and motion accuracy optimized by JD50 CNC system

Excellent Human-Machine Interaction

Structural design of front door, control console and worktable is in line with human operation habits

The overall structural design of the machine makes the maintenance of the components more convenient

Increase the magazine control box. It is convenient for the operator to change the tool

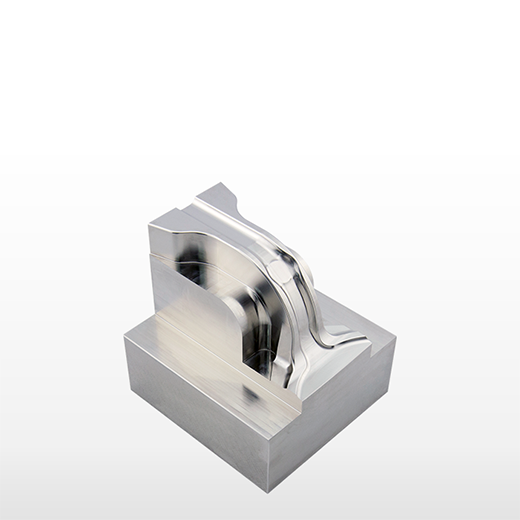

Example Workpiece

Related Links