VTA600

3-axis Machining for Product Processing

X/Y/Z Travel:23.6/ 15.7/ 13.4 in.

Spindle Speed:24000 rpm

Table Size:28.7 × 15.7 in.

Workload:661.5 lbs.

Highlights

Optimal Structure Design

The main structure of the machine tool is a single column and a cross slide. The column adopts the patented “inverted L” structure of Beijing Jingdiao, which has strong resistance to cutting and vibration

The rigidity of the bed, column and sliding seat is strong, which reduces the influence of structural deformation on the precision of the machine tool

Outstanding Machining Performance

With spindle cooling technology

The screw cooling technology is adopted to reduce the influence of the screw's thermal elongation

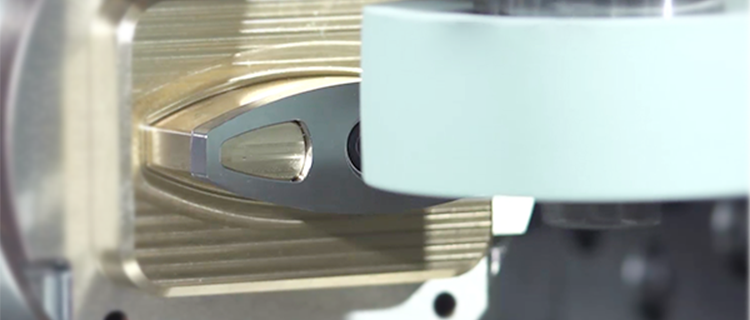

Achieve a variety of precision machining such as drilling, boring, tapping, milling and grinding

Excellent Human-Machine Interaction

The front door and side door windows are large for easy observation of the machining process

The front door adopts a safety door lock to prevent danger caused by misoperation during processing

The screw chip conveyor built into the bed has strong chip removal capability and reduces manual maintenance

Example Workpiece

Related Links